Power Semiconductors

Power semiconductor devices are increasingly in demand for their ability to accommodate high power and high voltages, using and transporting energy efficiently with minimal loss. Markets that especially benefit from the use of power semiconductors include automotive and mobility, consumer electronics, renewable energy, and other industrial applications that utilize power transmission and distribution. Examples of typical power semiconductor devices include metal-oxide-semiconductor field-effect transistors (MOSFETs), insulated-gate bipolar transistors (IGBTs), and power bipolar junction transistors (BJTs).

While silicon is still used for some of these devices and applications, compound semiconductor (CS) technology has become key to developing these advanced devices. The primary CS technologies in this space are silicon carbide (SiC) and gallium nitride (GaN) due to their wider bandgap, which reduces power loss and enables higher power efficiency than silicon alone. GaN-on-silicon transistors are much smaller than their silicon equivalents. The size improvement delivers cost benefits to the device makers and, therefore, to the developers of the end products in which the devices are used.

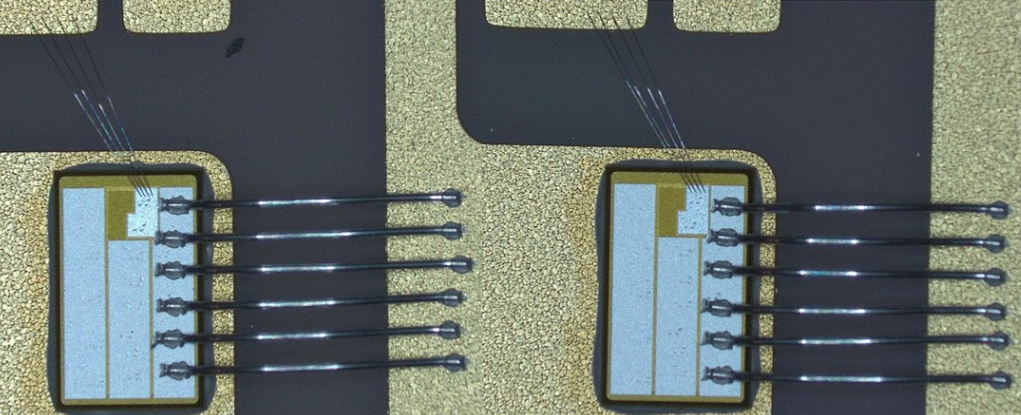

Since power devices are typically operated in harsh, high-temperature, high-frequency environments, their packaging and assembly must be equally robust. At the same time, they must be able to accommodate compound semiconductors’ unique properties. QP Technologies has a wealth of demonstrated expertise in collaborating with our customers to formulate packaging solutions for these devices.

We work with you to select the best approach for your device design, we develop and fabricate custom prototype packages to meet your specifications, and we then complete the assembly process using your die. This includes carefully thinning and polishing your SiC or GaN-on-silicon wafers and then precisely dicing them utilizing our state-of-the-art DISCO saws, which ensure the delicate CS materials aren’t damaged during the process.

Our power semiconductor capabilities include:

- Carrier Design & Fabrication (substrate, lead frame, metal tub)

Ceramic: DBC (ALN, AL2O3), BEO, ALN (THICK FILM), SI3N4, 3D Al2O3 with embedded cooling channels

Organic: Cores (FR4, Rogers, Arlon), stack-up technology

Lead frame:QFN (3×3 mm to 12X12 mm), custom lead frames (e.g., 64-lead TQFP-EP 10×10 mm)

OCPP:Remove old die and reuse package or substrate - Assemblies of Active devices (RF, digital, photonics, analog, mixed-signal)

GaN, GaAs, InP, SiGe, Silicon-on-Sapphire, SiC, graphene - Placement of Passive devices (caps, resistors, inductors)

Hardware (pins, connectors) - Final Package Manufacturing

System-in-Package (SiP): Combining various compound technologies into one final SiP

To download our white paper on the packaging solution leveraging compound semiconductor technology that we developed with Ideal Power for their B-TRAN™ bidirectional power switch devices, please click here. If you’re ready to engage with us on your power semiconductor substrate project today, please click here.