Mil-Aero Market

QP Technologies (formerly Quik-Pak) provides quick-turn prototypes and production quantities that meet this vital market’s stringent quality and testing standards. Complete MIL-STD and custom environment screenings are available. We are able to meet your production needs by delivering fast-turn onshore services – not having to ship your prototype overseas and wait for your small-volume manufactured lots to come back can be a critical factor in helping you to meet your time-to-market and cost goals.

Proven, innovative IC and board packaging approaches are essential to enabling system designers to use commercially developed components in military and aerospace platforms. Our offerings are ideally suited for this market, particularly with respect to RF requirements, as RF technology is vital for mil-aero devices.

Key to our RF capabilities is our strength in both flip chip and wirebond interconnect technologies. While flip chip is critical for smartphones, mobile, automotive, medical and other high-performance applications, wirebonding remains an important technology for mil-aero, as well as industrial, energy and other markets requiring robust, high-reliability solutions. Our wirebonding expertise includes heavy wire capability (5, 10 and 15 mil thicknesses), stand-off stitch for very low height, and tightly controlled wirebond lengths and loop heights.

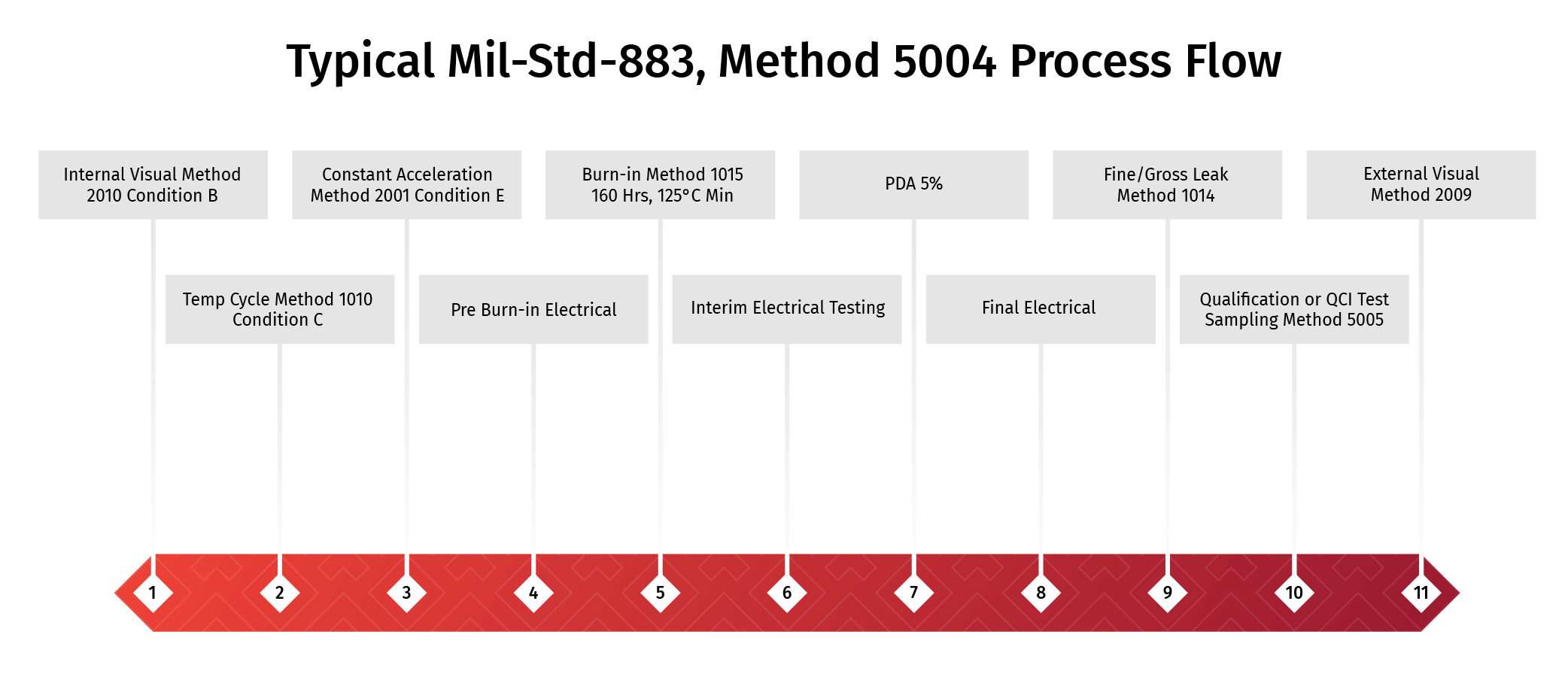

At QP Technologies, we can oversee your entire reliability/qualification flow for your mil-aero project, per the MIL-STD-883/M5004 Class Level B process steps:

To contact a QP Technologies representative and discuss your project scope and requirements, please click here, or call 858-674-4676.

QP Technologies is your reliable IC packaging partner to build the future of mil-aero applications through Open-Cavity Plastic Packages (OCPP).

Download our white paper to learn:

- How you can transform your plastic package dummies, test rejects, and excess inventory into ready-to-assemble components

- The value of an onshore solution for navigating around ITAR supply constraints

- The benefits from producing chip prototypes that are mechanically and electrically identical to future molded production parts

- Why Open-Cavity Plastic Packages’ (OCPP) longevity and durability specs make them an ideal solution for mil-aero machinery

The white paper details a real-world use case where dummy IC packages converted to Open-Cavity Plastic Packages (OCPP) passed stringent burn-in and MSL tests just like factory-fresh parts.

Download today to start unlocking the possibilities for your next IC packaging project.